Solutions

ïŧŋ

Contact us

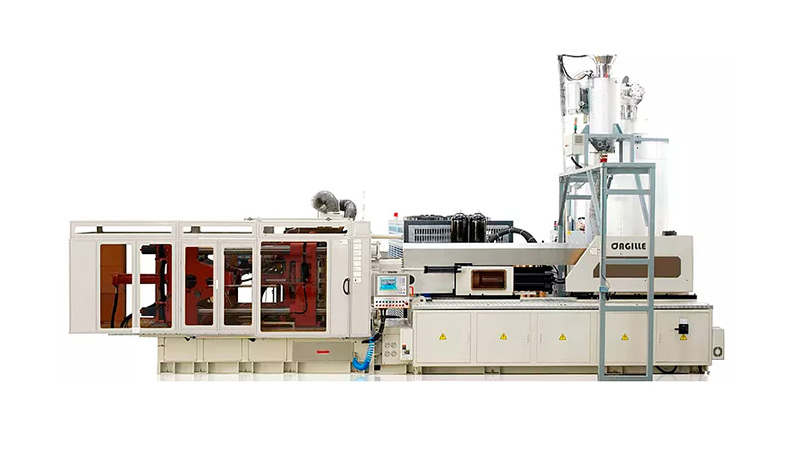

Preform injection

Efficiency in the manufacturing of high quality preforms with double thread equipments. A system with low energy consumption and maintenance, ensuring an efficient production.

The complete system includes: machine, mold with a hot chamber system and a robot with three positions per cavity for extraction and cooling.

MAIN FEATURES

- Double thread for synchronized load to reduce the cycle in 30%.

- Extrussor with insulation protection that reduces up to 40% of energy.

- CLP Siemens S7-300.

- Independent servo valves for pressing, extraction, injection and plasticisation movements.

- Removable plates for maintenance, without the need to low the mold.

- Three-station preform extraction robot with servo motor that enables fast and precise movements.

Molds

It has an independent cooling circuit, self-lubricating bushings and anti-wear guides to minimize maintenance stops. Stainless steel boards. Maintenance sensors from the transfer of the mold preforms until the extractor board or take out.

Individual cooling of the neck rings, improving the cycle and the dimensional stability. Perfectly balanced hot chamber that assures the distribution of the material flow is uniform, stabilizing the preform weight.

Balanced cooling channels, with turbulent water flow to guarantee a consistent cooling and an efficient heat transfer.