Solutions

Contact us

Polexseal

The sealing disks ensure more safety and resistance in the products, avoiding leaks, evaporation, and dryness in it. Ideal to seal pharmaceutical products, cosmetics, food, and chemicals, among others.

5 options available, according to the products’ application:

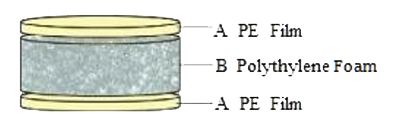

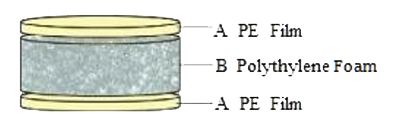

PSPE 300

- Laminated Polyethylene Foam Seal with PE film

- Density 300kg/m³

- Diameter 5-140mm

- Thickness 1-2mm according to the order

APPLIANCE

Cosmetics, food, beverages, and others.

FEATURES

Corrosion resistant, non-toxic, tasteless, smelless, acid and moisture proof, anti-mildew to increase the product’s lifetime.

COMPOSITION

The PE film is co-laminated on both surfaces of the polyethylene foam, enabling excellent barrier properties and insulation.

- Strain ratio in compression: 40% - 52%.

- Residual strain ratio: 14% - 18%.

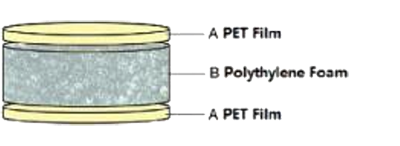

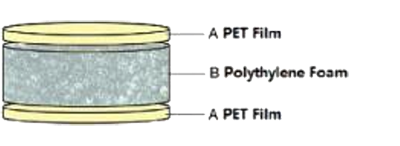

PSPET 350

- Laminated Polyethylene Foam Seal with PET film

- Density 350kg/m³

- Diameter 5-140mm

- Thickness 1-2mm according to the order

APPLIANCE

Cosmetics, food, beverages, and others.

FEATURES

Corrosion resistant, non-toxic, tasteless, smelless, acid and moisture proof, and anti-mildew to increase the product’s lifetime.

COMPOSITION

The PET film is co-laminated on both surfaces of the polyethylene foam, enabling excellent barrier properties and insulation.

- Strain ratio in compression: 40% - 52%.

- Residual strain ratio: 14% - 18%.

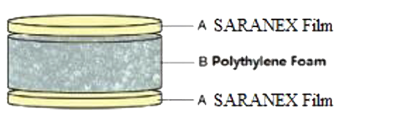

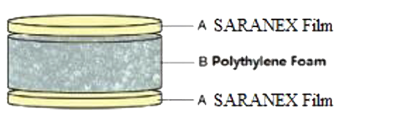

SARANEX

- Laminated Polyethylene Foam Seal with SARANEX film

- Density 250kg/m³

- Diameter 5-140mm

- Thickness 1-2mm according to the order

APPLIANCE

Cosmetics, food, beverages, and others.

FEATURES

Corrosion resistant, non-toxic, tasteless, smelless, acid and moisture proof, and anti-mildew to increase the product’s lifetime.

COMPOSITION

The SARANEX film is co-laminated on both surfaces of the polyethylene foam, enabling excellent barrier properties and insulation.

- Strain ratio in compression: 40% - 52%.

- Residual strain ratio: 14% - 18%.

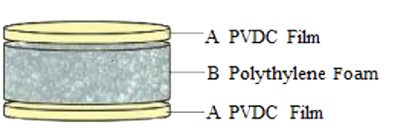

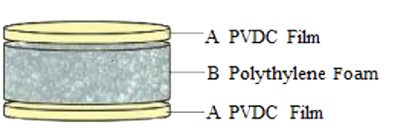

PSPVDC 350

- Laminated Polyethylene Foam Seal with PVDC film

- Density 350kg/m³

- Diameter 5-140mm

- Thickness 1-2mm according to the order

APPLIANCE

Cosmetics, food, beverages, and others.

FEATURES

Corrosion resistant, non-toxic, tasteless, smelless, acid and moisture proof, and anti-mildew to increase the product’s lifetime.

COMPOSITION

The PVDC film is co-laminated on both surfaces of the polyethylene foam, enabling excellent barrier properties and insulation.

- Strain ratio in compression: 40% - 52%.

- Strain ratio in compression: 40% - 52%.

PS 300

- Polyethylene Foam Seal

- Density 300kg/m³

- Diameter 5-140mm

- Thickness 1-2mm according to the order

APPLIANCE

Cosmetics, food, beverages, and others.

FEATURES

Corrosion resistant, non-toxic, tasteless, smelless, acid and moisture proof, and anti-mildew to increase the product’s lifetime.

COMPOSITION

- 100% PE foam

- Polyethylene foam of 102mm

- Strain ratio in compression: 40% - 52%.

- Residual strain ratio: 14% - 18%.